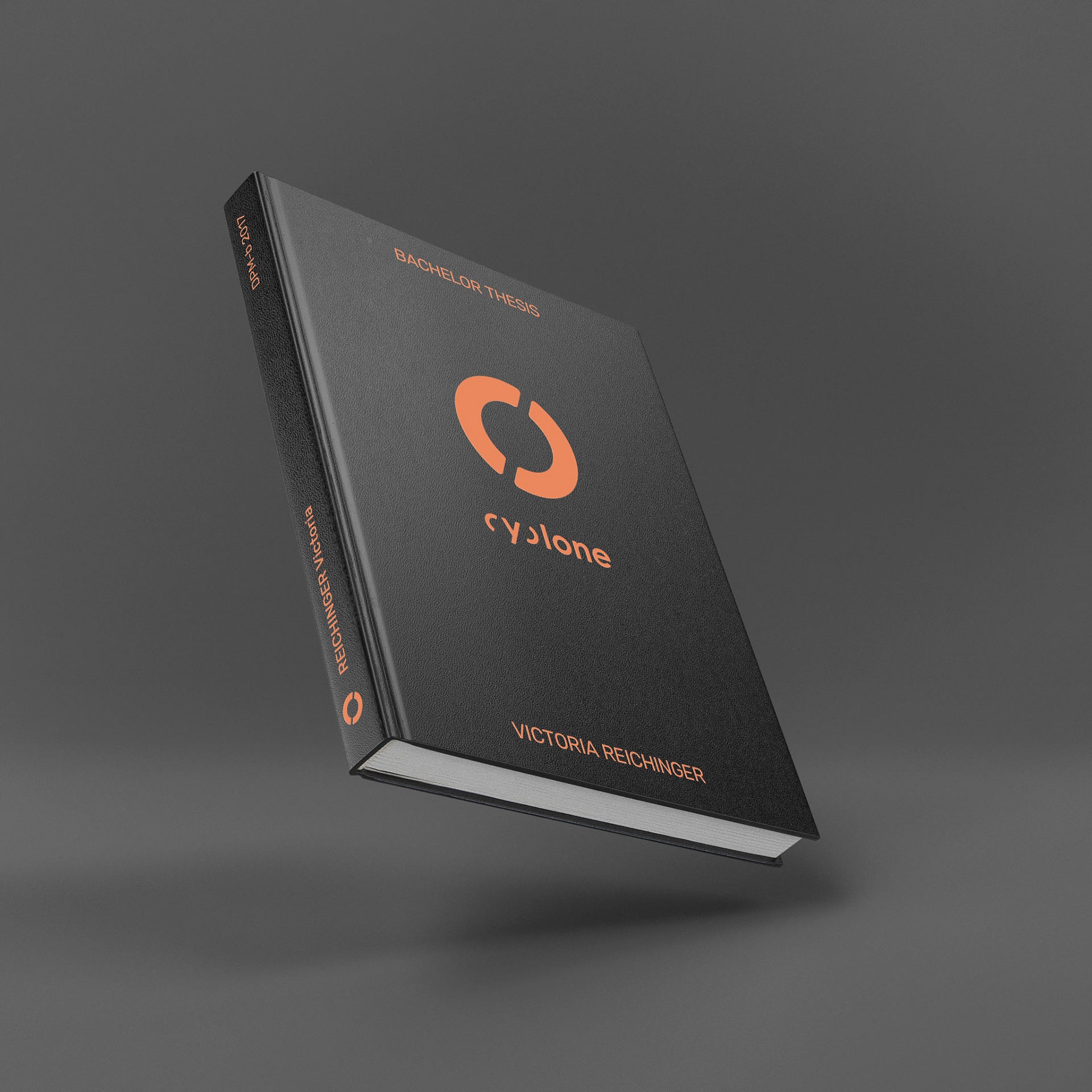

Refillable laundry detergent containers, made of recycled PP.

An integrated detergent dosing system prevents overdosing and wastage of detergent.

The replacement of the conventional concrete counterweight reduces the transport weight of the machine, providing a further improvement in the sustainability of the product. Empty water tanks make the machine 15 kilograms lighter.

The washing machine interface is reduced to the most essential wash settings. Each user can individually set and change their most frequently used settings via the Cyclone-App. Washing cycles can also be managed solely via a smartphone.

The Cyclone Washer is embedded in a circular business model. After a Circular Design Thinking process, the high-quality washing machine is produced locally and responsibly. Users pay a basic fee to be supplied with a washing machine. Their monthly bill depends on the number of wash cycles performed (pay-per-wash). During this period of use repairs and maintenance are included. When a customer returns their washing machine to the company, it is reconditioned and passed on to another customer. Doing so, a large amount of resources is saved.